Aircraft Docking System For Maintenance And Repairing Of Aircrafts

Repair and maintenance are an inherent part of aircraft performance management. Every aircraft, commercial or private, needs to pass through several performance parameters before they fly. An aircraft docking system is an ergonomically designed facility that helps in taking care of an aircraft. After landing or before taking off, the aircraft is taken to a dock for a thorough check-up. Only the rightly designed docking system helps the repair and maintenance workers perform their duties efficiently.

Purpose of an aircraft docking facility

The key to designing and manufacturing an aircraft docking system is to understand the aircraft from different angles, access an aircraft unit as per the requirements, and undertake the maintenance procedure. As such, every dock in use in an airbase, manufacturing unit, maintenance workshop, hanger, or elsewhere needs to be reliable and sustainable. It also needs to be easy for the maintenance and repairing staff members to access every part of the aircraft and a workstation for the free movement along with the aircraft in vertical as well as parallel dimensions.

Types of aircraft dock maintenance systems

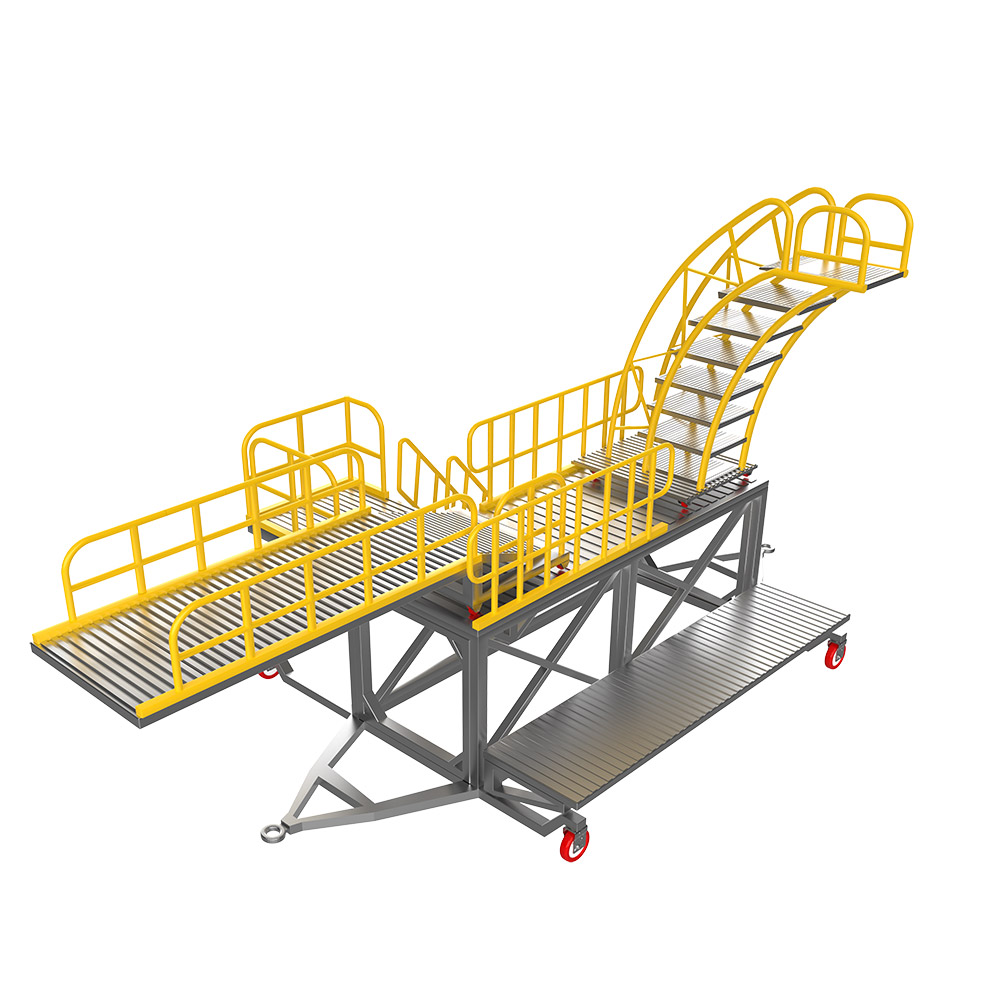

The docks can be suspended from the roof, floor-mounted, or integrated into other service units such as overhead cranes or mezzanine levels. A few most-used aircraft docks are as follows:

- Fuselage dock: The fuselage dock consists of the main work platform and front, rear, and upper wing-fuselage sections. Every part is edge supported with handrails. Top manufacturers like Affix scaffolding can customize the fuselage docks as per the requirements of the aircraft companies or maintenance units. Fuselage docks are movable and extensible.

- Nose dock: A nose dock is used for an aircraft’s nose maintenance purpose. It generally consists of the main platform, windshield platform, passenger door platform, and random platform. It makes these areas easily accessible to maintenance and repairing staff members and technicians.

- Tail dock: An aircraft dock maintenance system for the aircraft tail consists of a vertical fin platform, horizontal tail platform, and APU platform. On-demand, manufacturers equipped with state-of-the-art infrastructure and computerized machinery can customize a tail dock.

- Wing dock: A wing dock consists of an outboard platform, inner platform, the inner engine maintenance platform, the landing gear platform, and wingtip platform.

Every aircraft docking system is designed to adjust with C/D inspection services format and spray-painting jobs. The products also need to be standardized as per the international aircraft maintenance norms.

What the B2B clients can expect from a popular service provider?

- Ergonomically designed aircraft maintenance docks meet the purposes for which those are bought.

- Tailored solutions for different types of aircraft used in commercial and private domains.

- Appropriate advice and need-based support for any issue with the docking units.

- Repair and maintenance of the docking units as per terms and conditions or as agreed upon.

- Impeccable aircraft docking system within a client’s budget.

Comments

Post a Comment